Automation

Automation

The proportion of automation and digitalisation in the machine is constantly increasing. Production cells, autonomous set-up, monitoring functions and now the digital twin are features of HAUX projects.

Robot applications

Robots in the machine, outside the machine or between the machines for parts handling, operations or set-up, robots with one or two grippers, automation with cassette system and storage of disc packs, collets or gripper systems

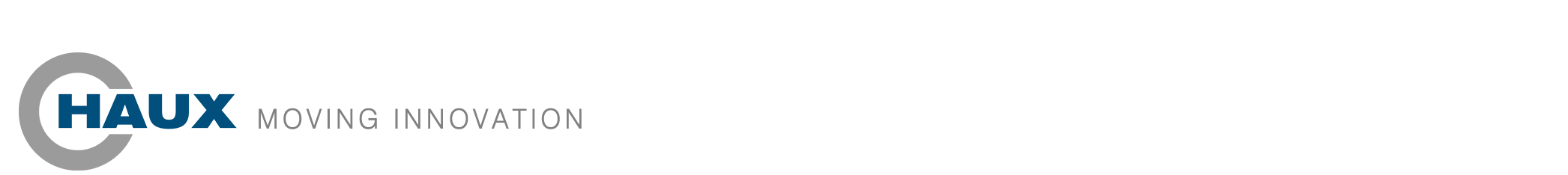

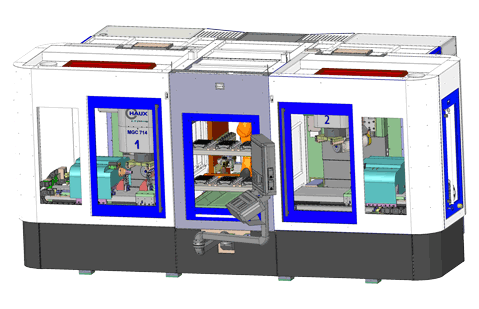

Robot in machine

Loading of parts and optional discs or collets from / into cassettes. The robot is located at station #2 or next to the workpiece carrier

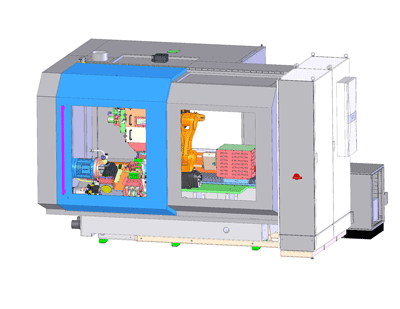

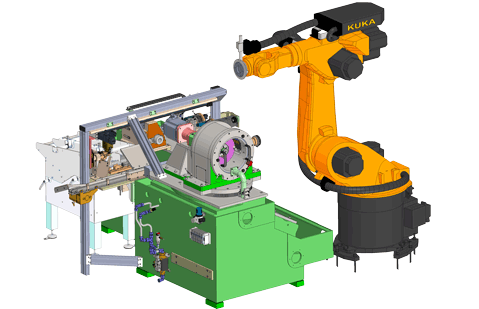

Robot in front of machine

Robot outside the machine in a separate unit. For small parts or parts weighing up to 50 kg from cassettes or special carriers.

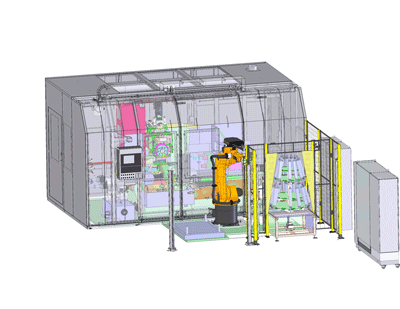

Robot on the floor of the cell for very large workpieces

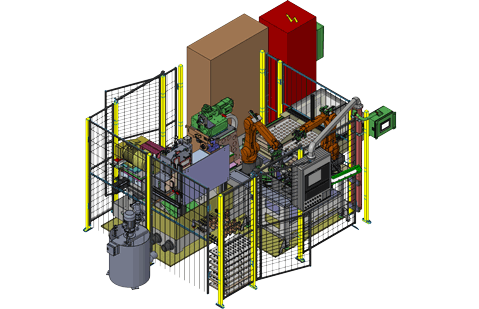

Cell

Robot interlinking of machines for handling parts between machines and storage solution

Robots between machines

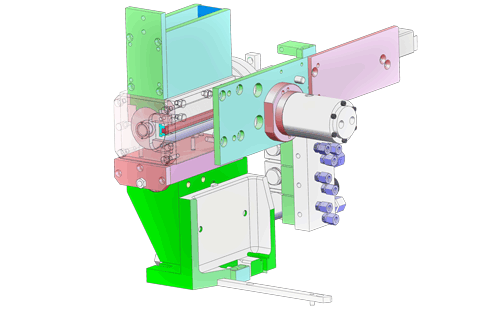

Robot for loading/unloading two stations with automatic setup for grinding wheels and collets

Robot loops

Patented process for grinding parts with robots in a special device with measuring systems

Robot handling

Automation concepts for complex handling processes with one or more robots and quick-change system

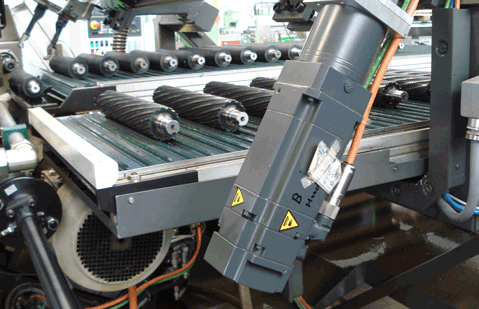

Handlings

2- to 4-axis handling with 1 or 2 grippers for loading from above or below the workpiece axis. The following are examples of 3-axis-solutions through to 4-axis-solutions with indexing station and high storage capacity

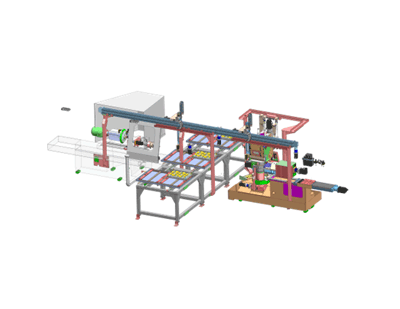

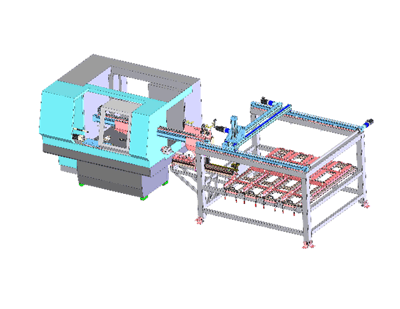

4-axis interlinking machines

Handling with 4th axis with gripper for loading into the machine, linking the machine and depositing in cassettes

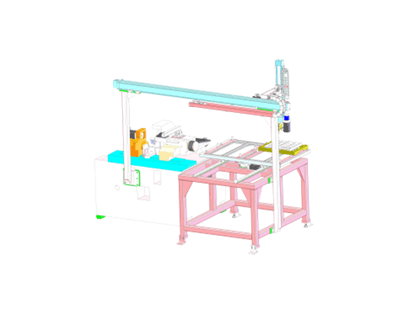

3-axis from above

Handling with gripper, loading/unloading the machine and inserting the parts into cassettes from above

3-axis from below

Handling with gripper, loading/unloading the machine and inserting the parts into cassettes from below

3-axis high capacity

Handling with gripper, loading/unloading the machine and inserting the parts into a large number of cassettes from above

Magazines

Conventional shaft magazines with additional counting or orientation functionality for high-volume parts.

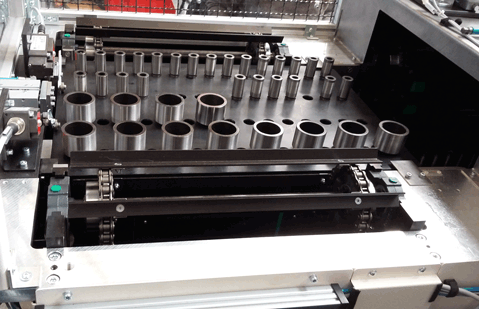

Shaft magazine

Magazine for handling cylindrical parts, especially for large quantities. With separating slide and additional removal/loading units

Roller magazine

Shank magazine similar, but for very small drills. With separating slide and additional unloading/loading units

Paternoster

Automated storage solution for transporting a large number of cassettes in a small space.

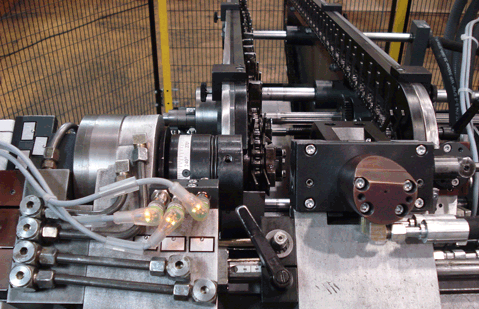

Chain magazine

Robust chain magazine for handling large parts with additional powerful unloading/loading gripper

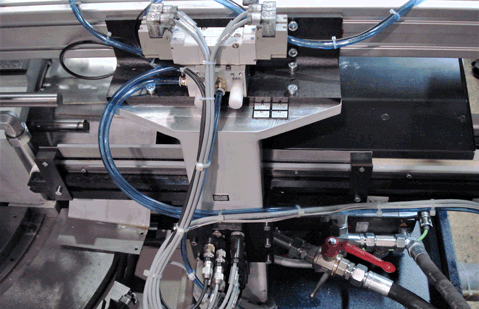

Band small

Tape solution for smaller parts or in addition to the shaft solution to measure parts outside the machine

Band large

Powerful conveyor solution for handling heavy parts, with additional strong gripper and in-case indexing system

Machine in the IT network

Implementation of preventive maintenance. Machine learning approach based on a calibrated machine.

EDGE Gateway

Real-time and logical processing of large amounts of data at the operational level of the machine. Connection of the machine to the internet/net with additional security.

Integrated machine

Interface of the machine for connecting to company data sources and for sending back machine data. This relates to data from parts, orders, tools or measurements.

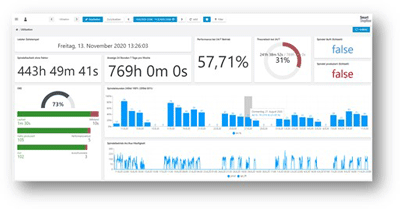

Monitoring

Dashboards that display the machine status according to the order, but also the condition of the machine with defined warning levels and error messages in general.

Intelligent machine

Implementation of preventive maintenance. Machine learning approach based on a calibrated machine.

Predictive maintenance

Tracking the history of components, saving the status on deceleration and redefining/defining warning levels for components

Process optimisation

Identification of patterns and success factors of relevant parameters to control and optimise machine performance on defined components

Machine learning

Still at the research stage, but with the aim of identifying and transferring solutions within a machine network to improve machine performance across the entire network