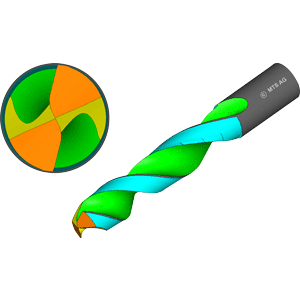

Machines

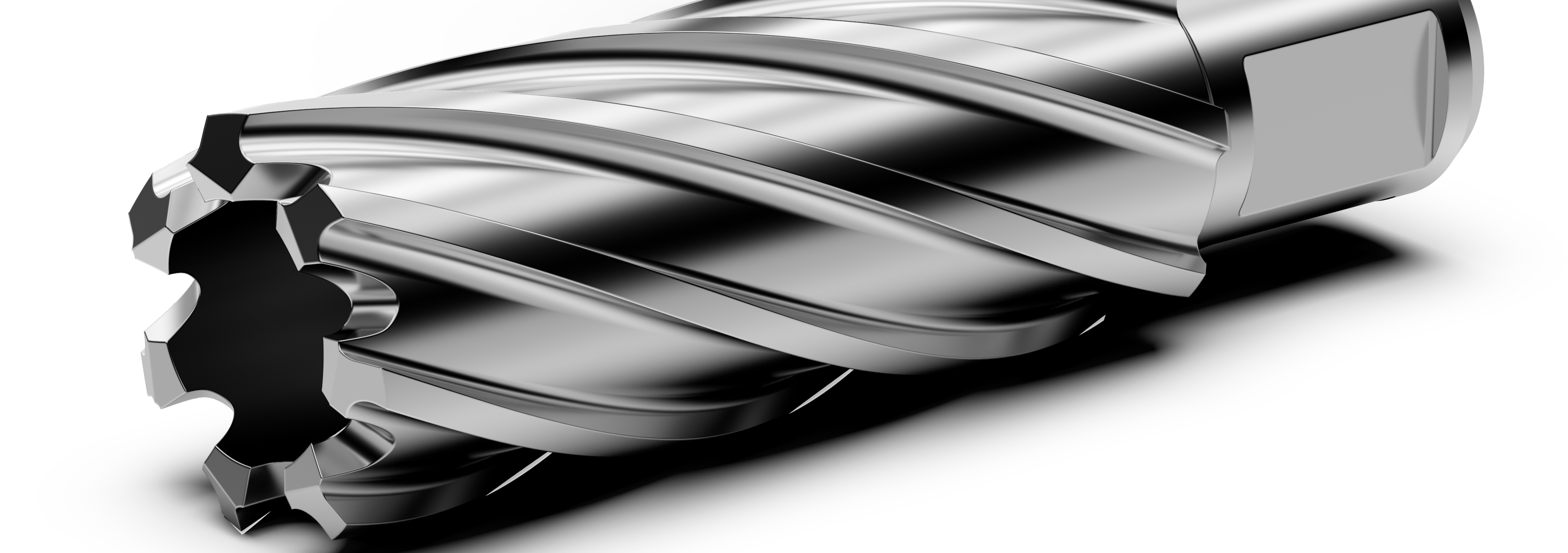

Tool Grinding Applications

Tool Grinding Applications

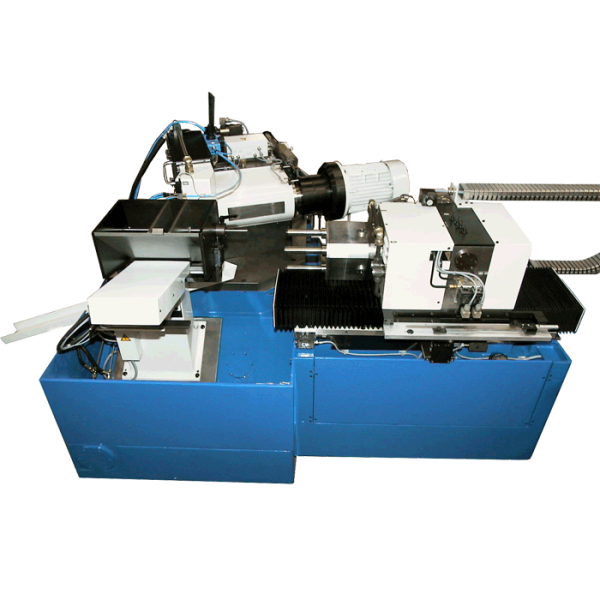

Machines for tool grinding with one operation as SINGLE summarized in S-Line, machines for all opterations as UNIVERSAL summarized in U-Line as well as machines with more than one operation as MULTI summarized as M-Line.

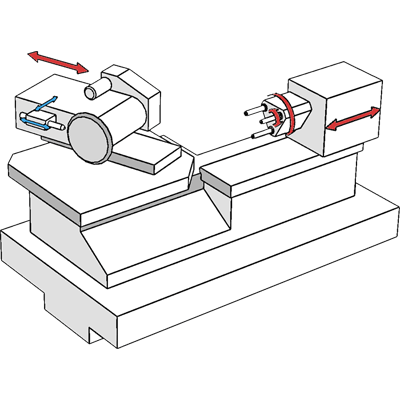

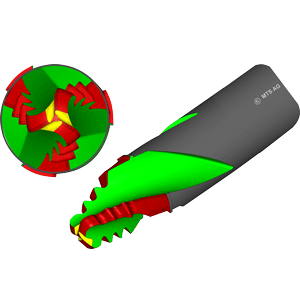

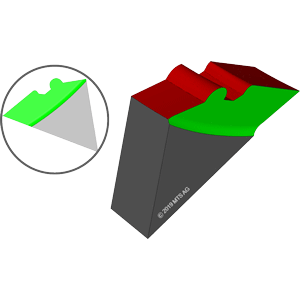

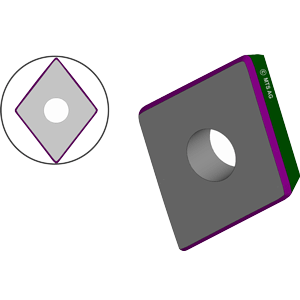

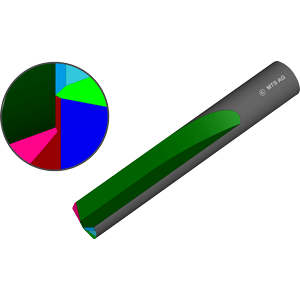

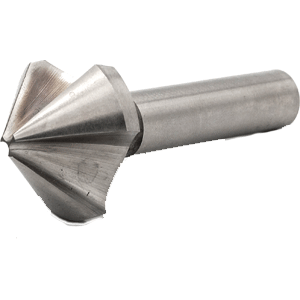

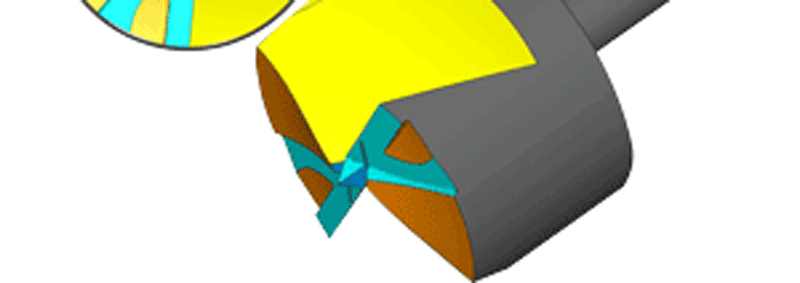

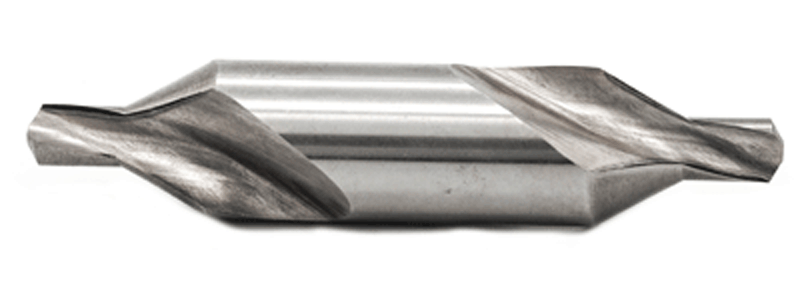

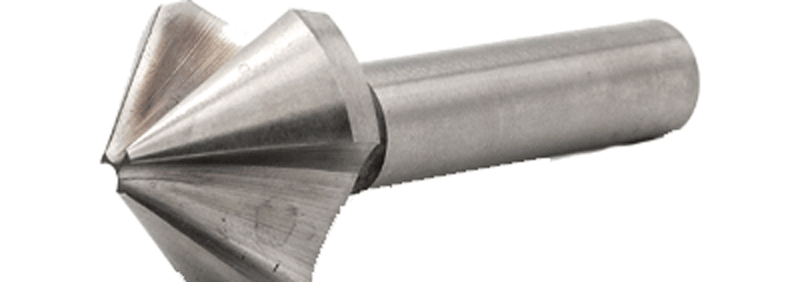

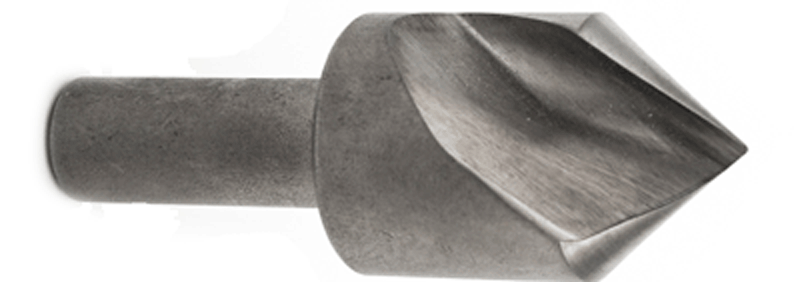

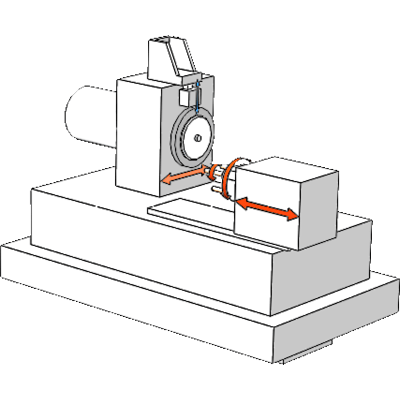

SINGLE OPERATION

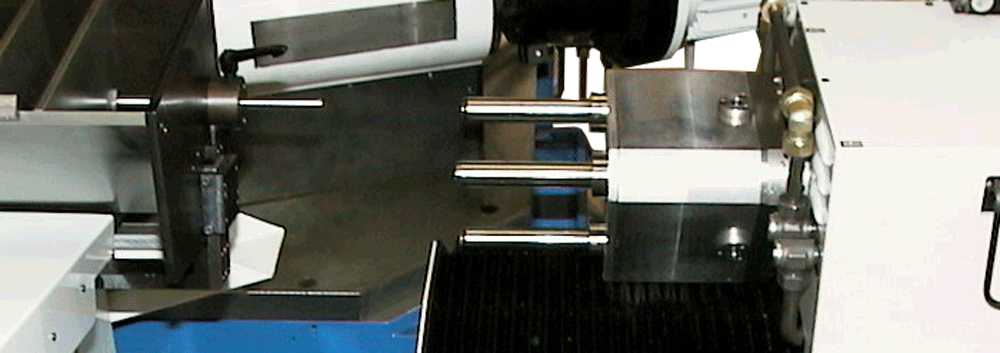

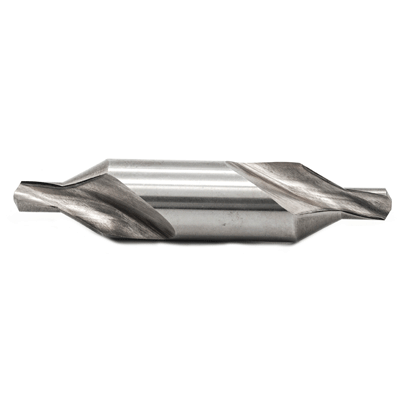

Machines for one operation with corresponding automation concepts. Reliable machines with HAUX-typical long service life. Machine lines are SP-Line for centre grinding (conical, split, pilot) and SM line for square or bevel grinding. Soon also the ST line for the thread grinding of tools and the SO line for the external cylindrical grinding of tools.

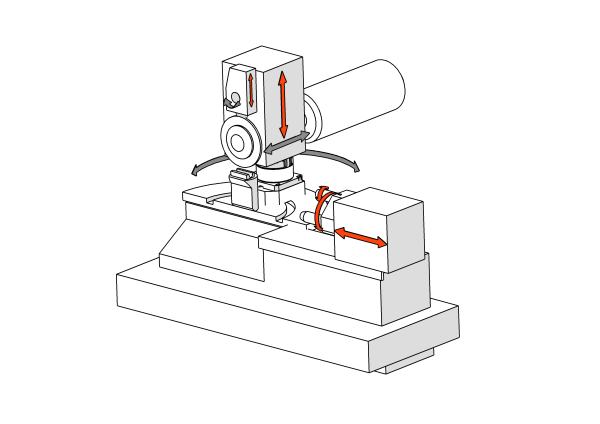

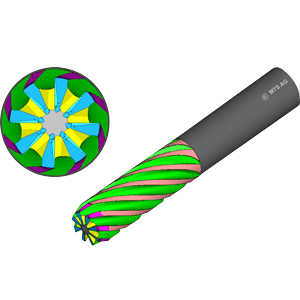

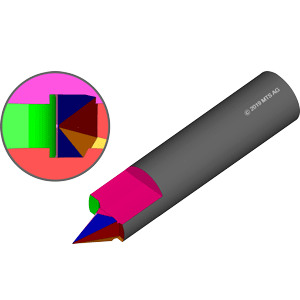

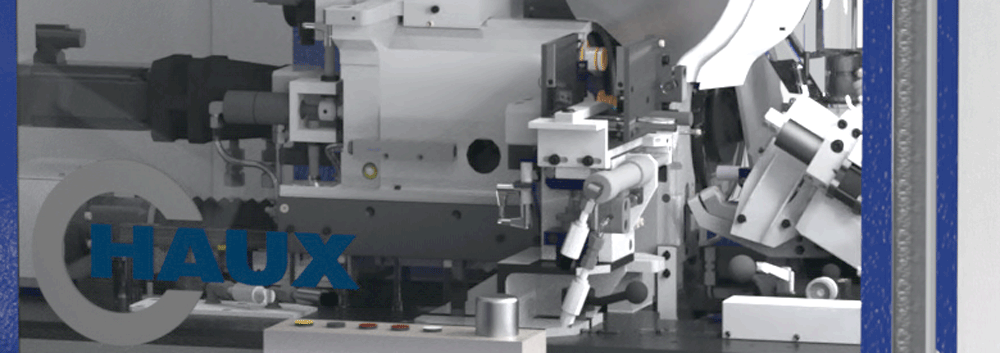

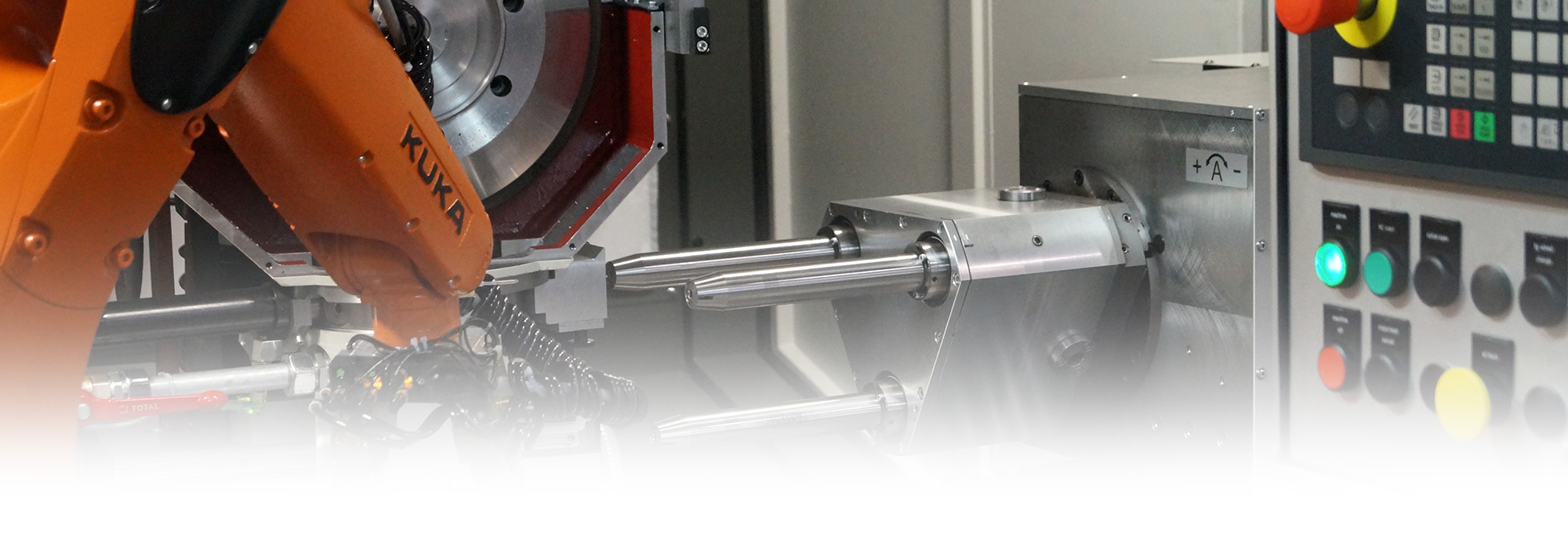

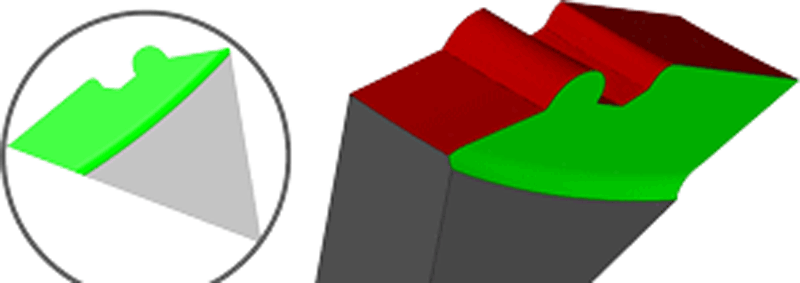

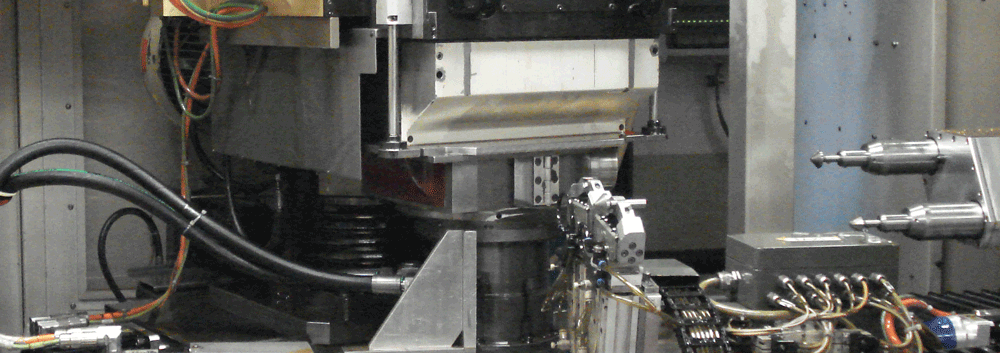

UNIVERSAL

Universal grinding machines in various performance and accuracy classes. Automation concepts from robot loading to integration into the IT infrastructure. UE-Linie 15 kW with modular design at the best price. UP-Line for highest accuracy requirements with 25 kW. UM line with 35 kW and UN line with 55 kW/90 kW for high performance with universal design and very powerful spindle drive.

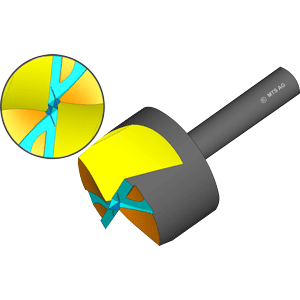

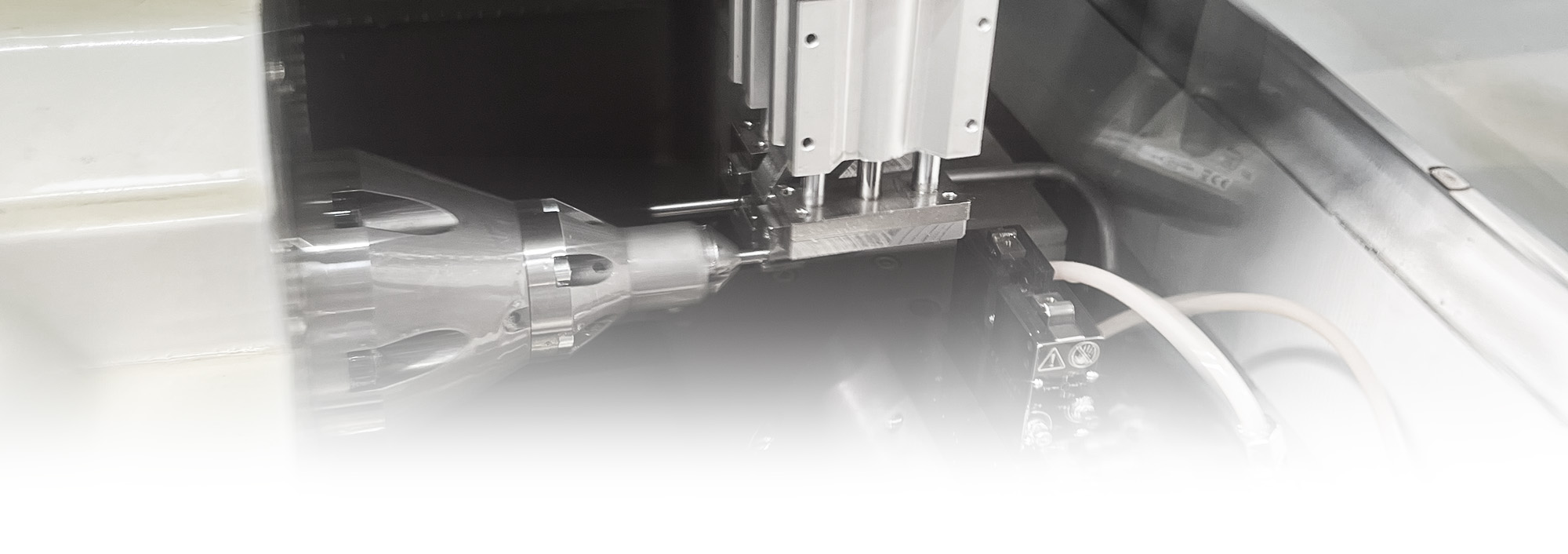

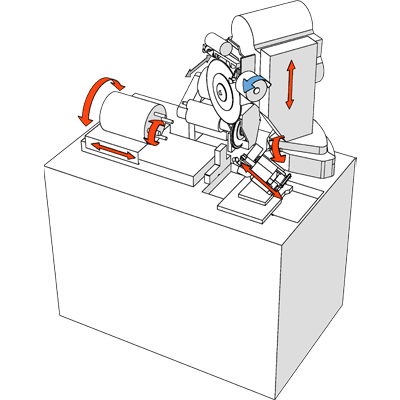

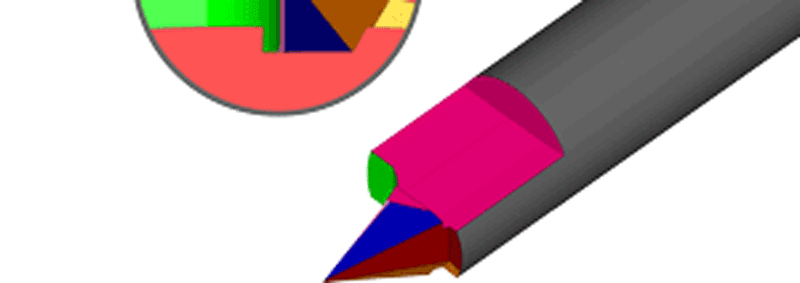

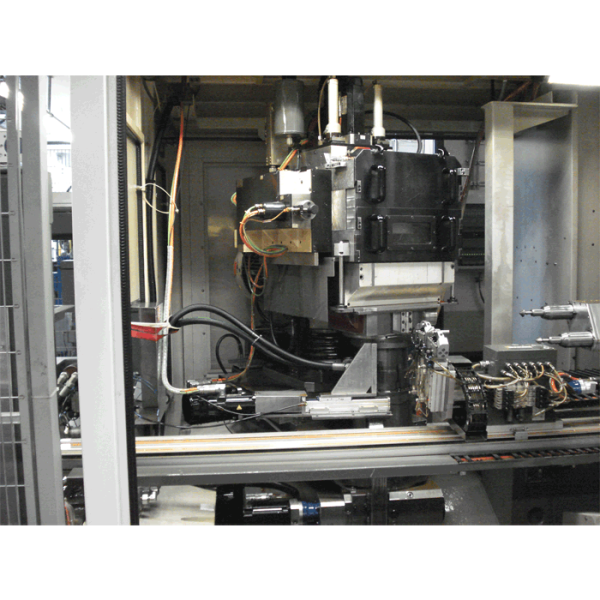

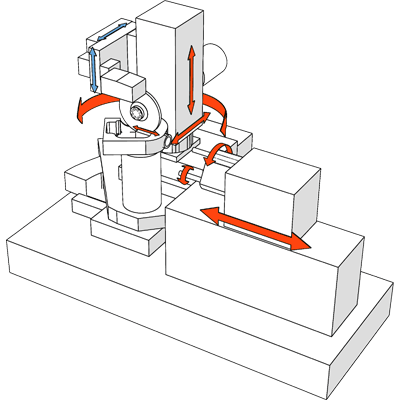

MULTI STATION

Machine concepts with 2 or 3 workstations based on a control unit on a basic body. High degree of automation and top-class efficiency, even with small batch sizes. MS-Line max. 3kW spindle power with 3 work stations (rough grinding, external and 3/5/6-axis finish), MM-Line max. 35 kW Rough grinding first station and modular second station. MN-Line classic machines max. 90kW, which originate from NU machines.