Technology

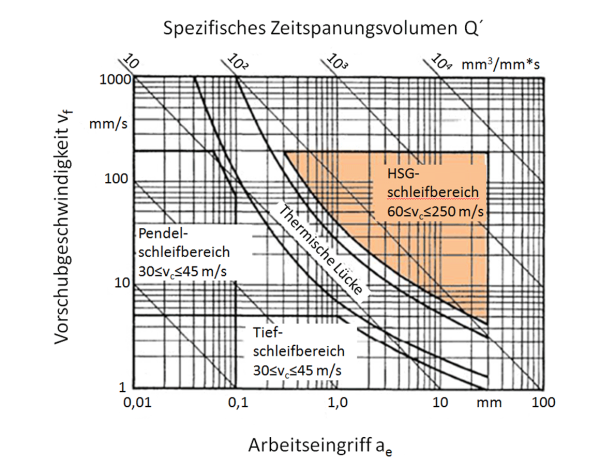

High-speed grinding

HAUX is a pioneer in the field of high-speed grinding. The HSG technology was developed by Dr Konrad Gühring until 1969. The advantages of HSG grinding are the highest Feed rate with high sanding quality and short cycle times.

The first machines based on the HSG technology concept were put into operation in the early 1970s. At that time, HSG became the trademark of High performance Systemtechnolgy GThe machine itself, as well as the grinding discs, coolant technology, control system and software, are all components of this system.

Modular machines

A modular concept in conjunction with high-quality parts enables the construction of customised machines to meet specific requirements. Modules such as workpiece carriers, tool carriers or automation can be realised as a finished machine in a relatively short time.

Counselling

HAUX not only stands for the manufacture of special grinding machines, but also offers support in the selection and definition of processing machines, the associated automation, the equipment of the machines and the integration of the machines or production cells into the company's IT infrastructure.

The machine is selected on the basis of work processes, the technical design of the machines is based on the modules and the commercial assessment is primarily based on cycle times and quantities. Depending on the application, automation may include magazine or robot solutions, for example. Software, the utilisation of machine data and the integration of the machine into the operation are becoming increasingly important.