Accessories

Special devices

Measuring devices for tools in the workshop in oily environments through to automated measurements in the quality department. Starting with the robust AMP 100 next to the grinding machine, over the AMX 100 with automated measurements that AMZ 100 with "red light" for carbide tools and the process-automated AMZ 200 with servo-driven axis for adjusting the tool. See also bending machine for taps as special accessory.

AMP 100

Former PG 100 on the market for decades. With digital display and manual documentation. Prism and 90° working radius. With lens system and very robust.

AMX 100

Camera-based solution with predefined measurement processes and automatically filled Excel templates. Normal white light. Prism for tool and 90° working radius.

Video (Youtube):

HAUX AMX100

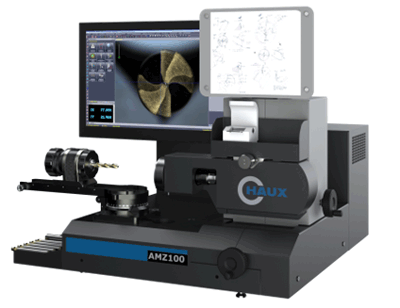

AMZ 100

Camera-based solution with automated measuring sequences and all the functions of the AMX100. Special red light for carbide. Collet holder and 360° working radius.

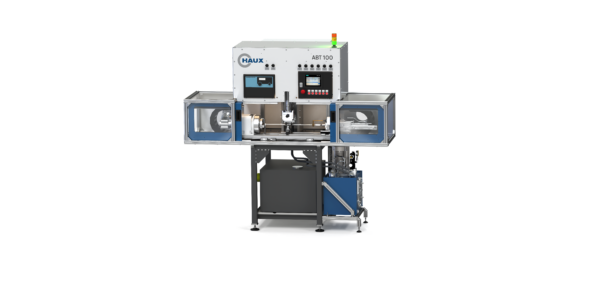

Bending device

Straightening of long taps with bending device Manual loading of taps and parameterised software.

AMX100 MAX

Tool Measuring Device

Premium version of the AMX100 with high-end camera and accessories

ANGLEmaster

cutting angle

Precise cutting angle measurement for taps

Accessories

Special accessories to extend the functionality of our sanding machines. These accessories, such as the GDS flexible clamping system, RENISAHW measuring probe, centring system, AROBOTECH holder and much more, are primarily focused on universal grinding machines. Standard accessories such as collets, bushes and guide plates are part of the machine range.

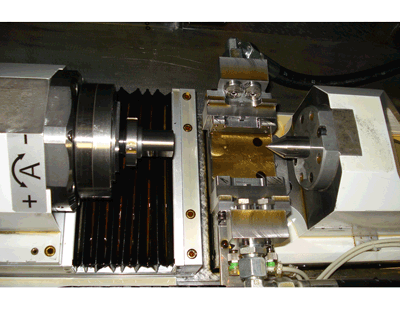

Flexible clamping system GDS

Flexible clamping system for cylindrical tools from 3 to 20 mm diameter, mainly for automation. Adjustable concentricity for maximum quality.

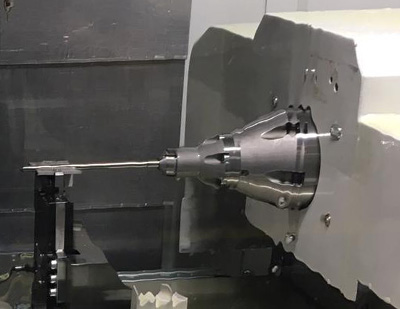

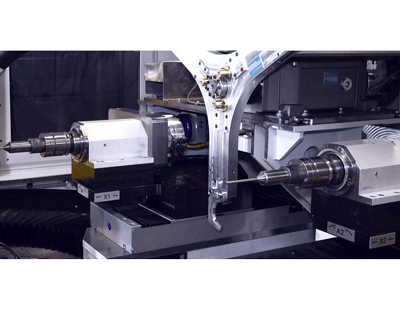

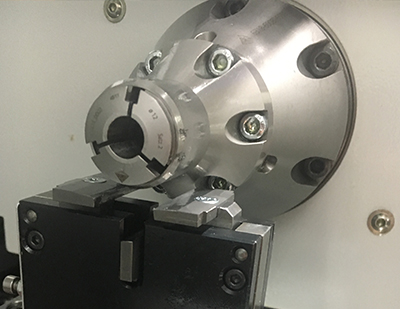

Centring system

Solutions for holding workpieces between centres in the range from small to very large workpieces. Interchangeable centre and optional servo axis and pressure control.

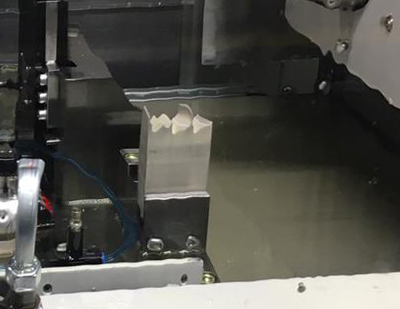

Cooling chamber

Solutions for grinding workpieces with high infeed in a bushing and coolant chamber in the range from small to very large workpieces. Modular concept for preparing the coolant chamber outside the machine for quick setup.

AROBTECH clamping system

High-precision centring support with 3-position fixation using carbide plates that cover a defined diameter range.

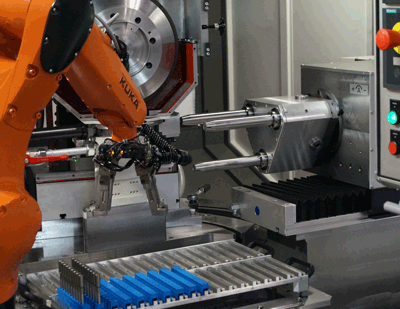

Gripper system

Mounted on robot or gantry solutions primarily for handling parts, but also for disc sets or other tools.

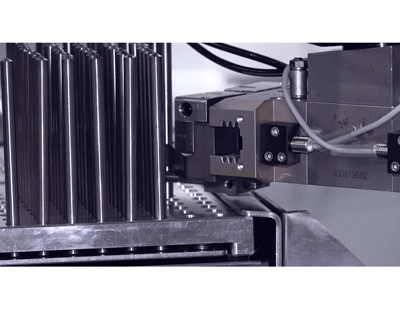

Cassette system

Various cassette solutions from the REISHAUER basis to customised cassette systems with optional modular setup.

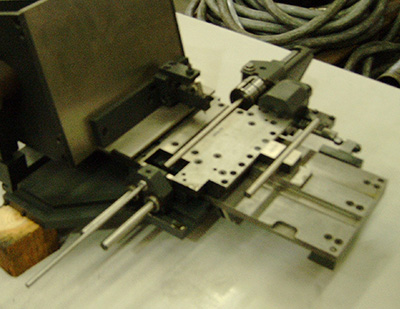

Axles for support

Special solutions for grinding with high infeed that integrate the horizontal or vertical servo axis into support solutions, such as for grinding with a bush or with a prism.

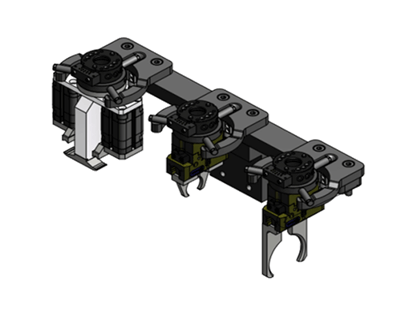

Quick-change double or triple head

HAUX classic solution for quick-change systems of MULTI station machines for simultaneous grinding on stations and unloading of parts.

Quick-change clamping units

Quick-change system for universal sanding for unloading/loading during sanding. Can be used on MULTI stations as well as on standard 5-axis machines.

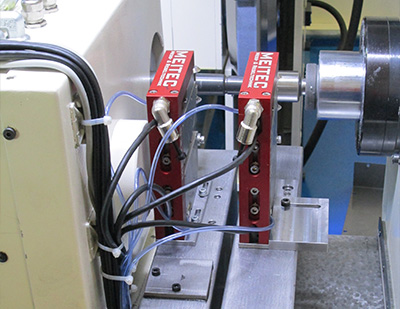

RENISHAW probe

Measuring probe on the headstock with additional axis for approaching the position for measuring the tool.

BALANCER

Balancing system integrated in the spindle or mounted on the flange for maximum accuracy on the tool.

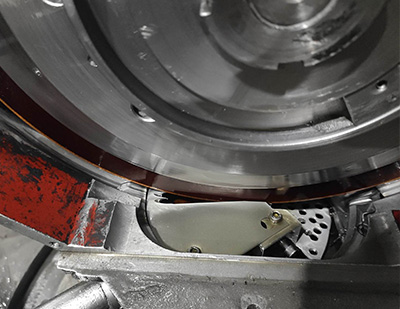

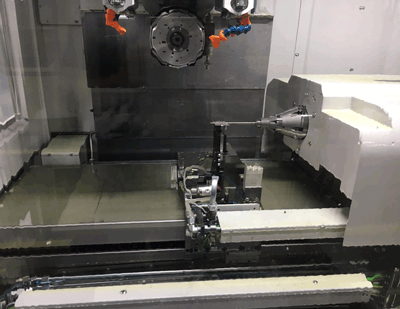

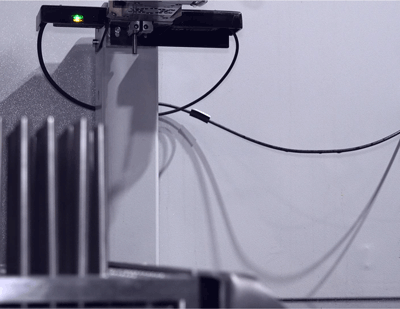

Measurement in the process

In-process measuring devices for the external cylindrical grinding process. Mounted on the workpiece axis with additional axis to be able to move onto the part.

Laser view

Collets

Standard and special collets for holding workpieces in workpiece carriers.

Guide plates

Is required in magazines to allocate the tool before loading it into the workpiece carrier.

Disc conditioning

Roughening of the disc on an additional station to improve the cutting of the disc when mounted on the machine.

NU Synchronous motor spindle dressing device

The Meyrat MDS-58 synchronous motor spindle achieves up to 25,000 revolutions per minute.

NU Hydraulic dressing device 2.0

The new hydraulic NU dressing device improves every single aspect of its predecessor. Increased service life, extended service intervals, easy set-up and increased performance and reliability.

Clearance nozzles

In-process cleaning of the disc with additional nozzles for cleaning the grinding disc in the process.